The basic tool for producers of interior roller blinds is a station for cutting fabric. The cutting tables for fabrics (SRM) that we propose, are addressed to large and small producers as well as to people who are just starting with production. A wide selection of cutting tables will satisfy various needs.

For small companies and for those who have just launched production, and who seek solid but reasonably priced work stand, we recommend Budget type of tables and the new table in our offer – a table with pneumatic cutting. For companies which value quality and efficiency, we recommend Standard and Premium type of SRM. 3 types of sizes and lots of additional options in all types of table are available.

On special request we can make diffrent size of table and equipt it according to customer’s requirements. An electric disc cutter in a basic kind of tool, and in Premium version, electric disc cutter and ultrasonic knife (used interchangeably). The ultrasonic knife cause smooth and not frayed cutting and that’s why it the best option for difficult fabrics.

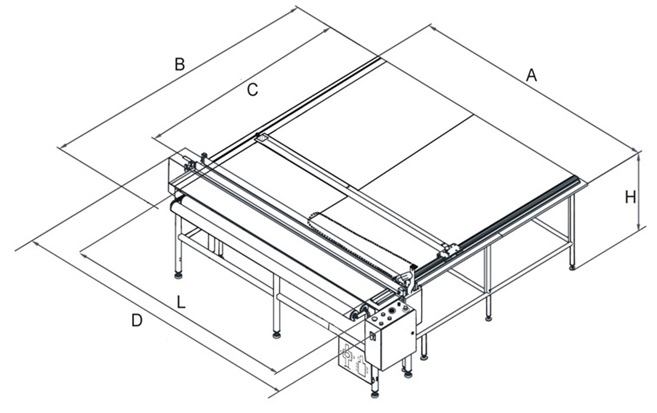

| Table type | A – top width | D – total width | C – cutting length | L – cutting width | B – total length |

| SRM Mini | 2450 | 3250 | 2750 | 2450 | 3450 |

| SRM Medium | 2750 | 3250 | 2750 | 2750 | 3450 |

| SRM Maxi Pneumatic | 3000 | 3270 | 2750 | 2950 | 3450 |

| SRM Maxi | 3100 | 3600 | 3000 | 3050 | 3550 |

SRM Budget

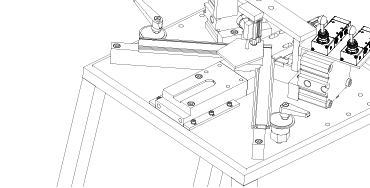

It’s the simplest type of cutting table. Depending on the selected size, it can feature electric cutting knife or manual, off-the-shelf knife. Clamp also depends on that – Medium size features a double pneumatic clamp, and Mini size is provided with a single manual clamp. Regardless of the size and knife, the operating mode is manual (it means that operator moves the knife manually). Since the table equipment is minimised, the price is very attractive and it provides a perfect solution for start- ups that purchase their first fabric cutting station. The main advantage of the table is solid linear guide fitted with a carriage, which carries a disc cutter. This solution provides high precision and a very long service life of the device.

| Table Type | Operating mode | Cutting | Clamps | Footswitch / start cord | Long ruler | Backlight |

| SRM Mini Budget | Manual | Manually | Manual | None | None | None |

| SRM Medium Budget | Manual | Electricdisc cutter | Pneumatic | None | Optional | Optional |

SRM Standard

Higher version of fabric cutting table, featuring as standard an electric disc cutter. Contrary to Mini versions, where the operator operates the cutter manually, larger tables feature automatic cutter operation. In this case the table is operated via a touch panel. The option available in the software include: detection of material run-out, setting of clamp function (lowered or raised clamp at cutter return), setting of cutter speed or simple setting of cutter travel distance. Further to that, the panel displays cut counter and enables language selection upon activations (Polish/English). In order to modify advance table settings the operator must log in.

Basic equipment of the Standard version features LED illumination of the cutting sucker and double pneumatic clamp. With this equipment plus excellent price-quality ratio, it is the most popular table model.

| Table Type | Operating mode | Cutting | Clamps | Footswitch / start cord | Long Ruler | Backlight |

| SRM Mini Standard | Manual | Electric disc cutter | Pneumatic | None | Optional | Yes |

| SRM Medium Standard | Auto | Electric disc cutter | Pneumatic | Optional | Optional | Yes |

| SRM Maxi Standard | Auto | Electric disc cutter | Pneumatic | Optional | Optional | Yes |

SRM Premium

The highest version of the SRM cutting table in our offer. The table is equipped in two interchangeable knives: electric disc cutter and ultrasonic knife. The touch panel is used for the insertion of standard settings – the operator inserts the length of the produced blind, switches on or off the sensor of the end of a fabric (the knife is moving only to the length of the material, not the table), and it is also possible to change the speed of knife movement – at the beginning and later, normal movement – which is very important when the ultrasonic knife is in use. With this option the operator can choose the best speeds for every, even the toughest fabric, and later, save the setting for 25 types of fabrics. Switching between the knives is very easy and takes no longer than 1 minute.

Premium version features all equipment options of the Standard version. Additionally, the table is equipped in a long ruler paced across the width, the LED backlight on the cutting section, a startup cord under the working table, and manual centering system under the worktop. This configuration makes the device very efficient and it can be further improved by adding additional options.

| Table type | Operating mode | Cutting | Clamps | Footswitch / start cord | Long ruler | Backlight |

| SRM Medium Premium | Auto | Ultrasonic knife | Pneumatic | Yes | Yes | Yes |

| SRM Maxi Premium | Auto | Ultrasonic knife | Pneumatic | Yes | Yes | Yes |

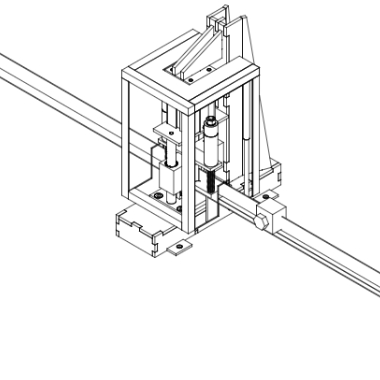

SRM Pneumatic

New in our offer. For those seeking to buy a large table, reliable and simple to operate.

Cutting with replaceable off-the-shelf blade and pneumatic actuator responsible for blade

travel. For this reason it is necessary to have to a compressed air network. The module is

equipped with a double pneumatic clamp and an optional LED backlighting (requiring

connection to a regular power outlet). Due to the fact that the blade moves rapidly at the end of the table a sophisticated control system is not possible. Just like on other tables, we can install a manually regulated ruler or with a digital display or equip the table with an additional shelf, or a folding shelf “carved” from the table top (facilitating access to fabric on the table top – detailed description can be found in additional options).

| Table Type | Operating mode | Cutting | Clamps | Footswitch / start cord | Long ruler | Backlight |

| SRM Maxi Pneumatic | Auto | Pneumatic knife | Pneumatic | Optional | Optional | Yes |

Additional options

- Ruler over the entire width of the table enables the fabric to be accurately aligned to the required measure and angle. The ruler can be adjusted and locked manually with distances indicated by measures stuck to the table – in basic version. A higher version features a ruler with magnetic stripe and digital display for measurement read-out. Top version features a ruler controlled with touch panel used for entering the measurements of the fabric being cut and the ruler automatically moves to the pre-set position.

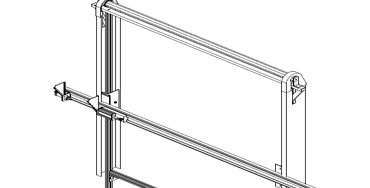

- System for rolling out fabric involves a ruler with grippers. This is an additional simplification for the operator – their task here is only to enter the dimension piece and the ruler will stretch the material to the required width of the table. The operator must unfold the material to the blade, then turn and remove the piece when it is ready.

- Automatic unwinding fabric feeders is an additional convenience when buying a fabric cutting table with a gripping ruler.

- Material Backlighting Backlight on the module is one of the standard options for the SRM roller blind cutting table, but the backlighting surfaces can be additionally increased by the area of the entire work table or only part of it. In this case, we use LED panels under a worktop made of impact resistant milk glass.

- Manual fabric roll centering can be done manually – the SRM table operator can use special wheels underneath the table top to move the roll in the correct direction so that the fabric is perfectly adjacent to the side band. This process can be automated.

- Pneumatic back clamp with assembly tray with dies (holders for blind’s tube) for those seeking to use the most of table capabilities and size. This solution provides an assembly station at the end of the table for folding the blinds (practical solution for systems, where fabric tip must be forced in tube channel).

- Underneath the work table top, at 1⁄3 or 1⁄2 of the length of the work table the operator can place a shelf, which can be used to gather components, fabric or ready roller blinds Additional shelf under the table top.

- In the case of large tables, particularly very wide tables, we recommend a table top with a fold out shelf 60 cm wide. The unfolded shelf is a part of the table top, however when folded it enables easier access to the fabric in the middle of the table. The shelf is held by gas actuators, so that it does not fall during operation and does not hit the table top when it is closed.

- Worktop elongation to 4 m.