In cooperation with Jackmeister, we have created production workstations for every necessary tool. These are, among others, tables for cutting strips, tables for cutting fabric s, for drilling holes in pleated blinds, as well as tables for assembling pleated blinds, i. e. for pulling through strings and finishing pleated blinds. Each workstation has a bottom shelf for storage and, where necessary, a manual gauge with bumper is fitted (on request the gauge can be equipped with a digital distance indicator or fully automated).

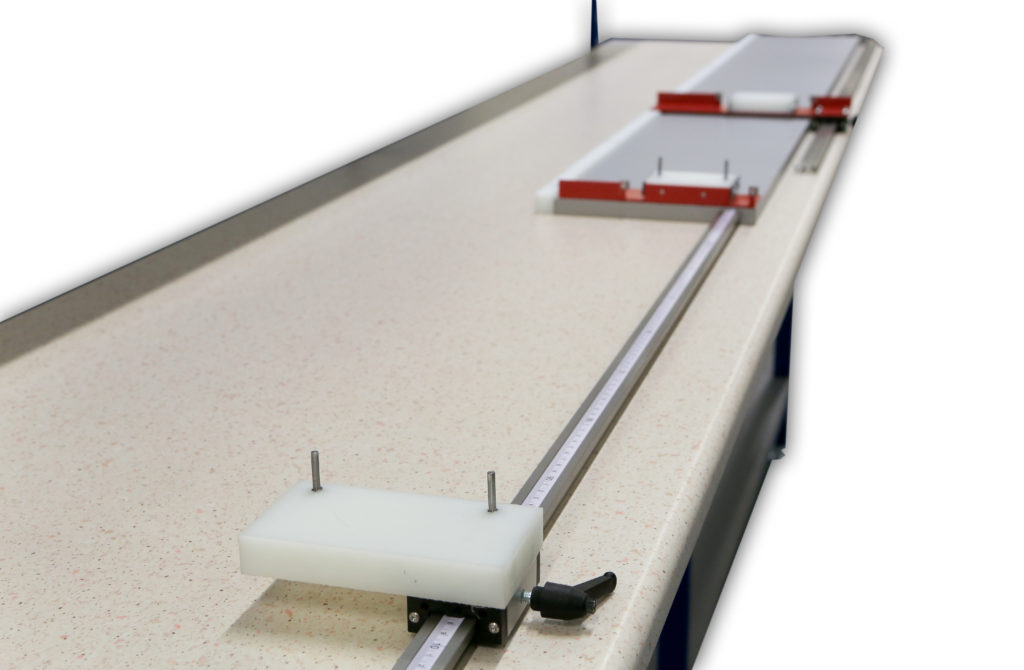

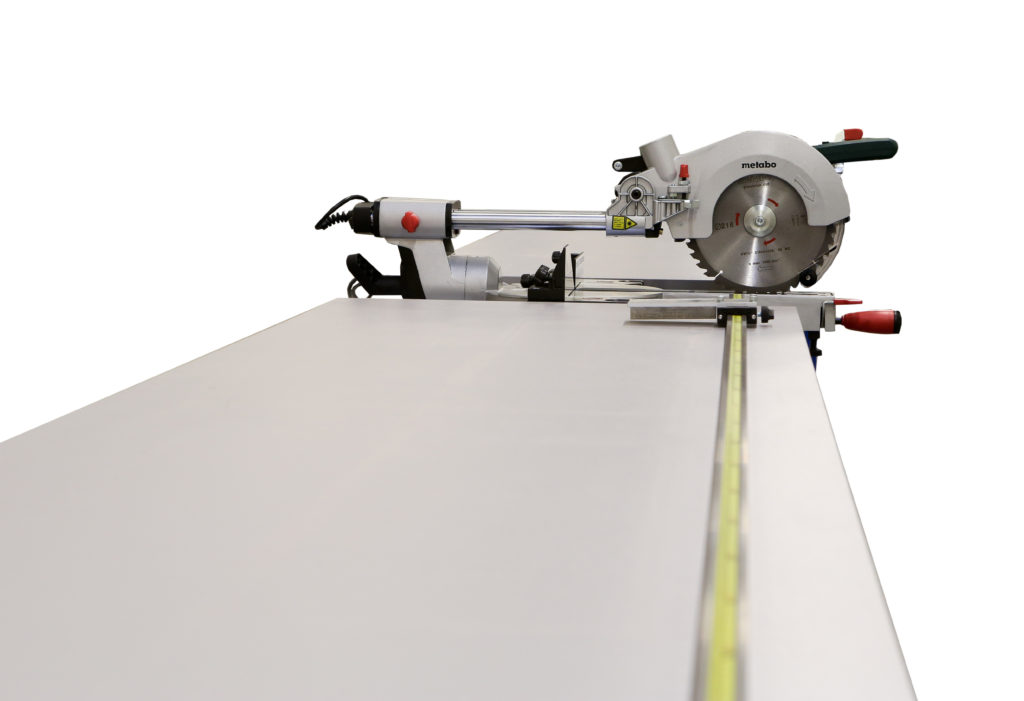

Cutting table for profiles PPS-P

Components of the table:

– Worktop at the input with a length of 2m,

– Shelf below the saw,

– Worktop at the output with a length of 2.5m with a gauge and bumper,

– Bottom shelves for storing production elements

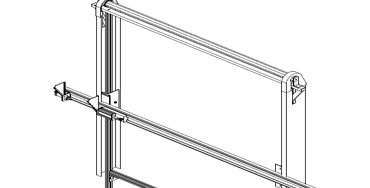

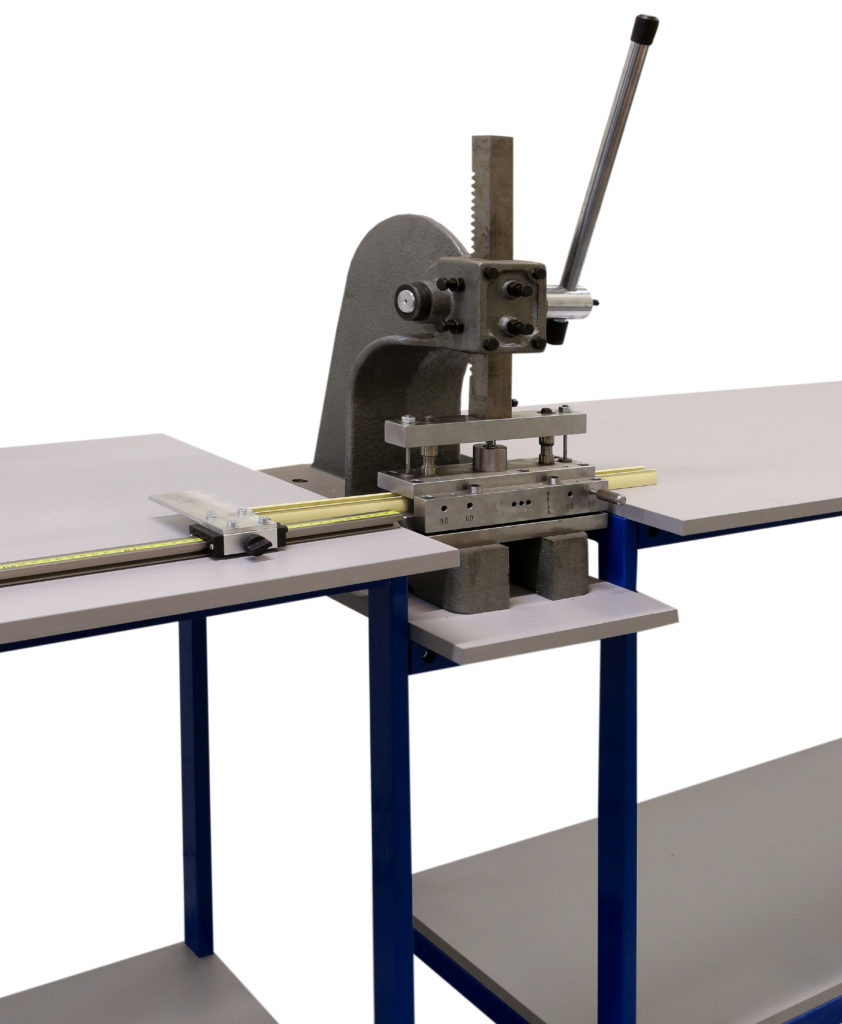

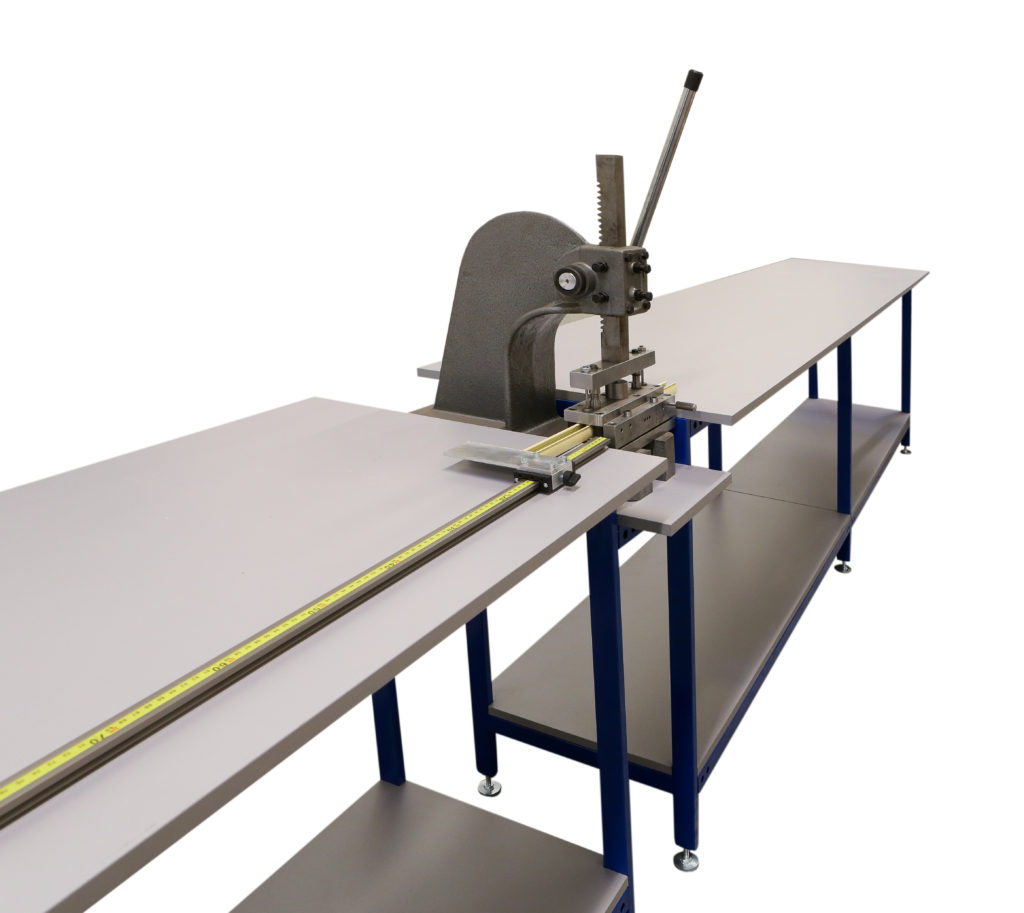

Table with a press for punching holes in rails PPS-L

Components of the table:

– Worktop at the input with a length of 3.0m,

– Shelf under the press and the die,

– Worktop at the output with a length of 2.5m with a gauge and bumper,

– Bottom shelves for storing production elements

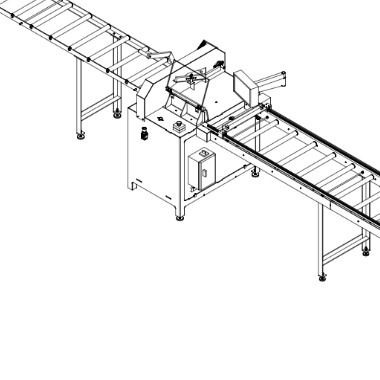

Table for cutting pleated material and for drilling holes in pleated fabric PPS-T

Components of the table:

– Worktop at the input with a length of 2.0m,

– Shelf under the saw to cut the fabric,

– Worktop central intermediate with a length of 2.5 m,

– Shelf below the drill,

– Worktop at the output with a length of 2.0m,

– Bottom shelves for storing production elements

Table for assembly pleated blinds – PPS-M

Components of the table:

– Worktop with a length of 3.0 m for the assembly of “spider” material

– Top shelf for elements,

– Bottom shelves for storing production elements